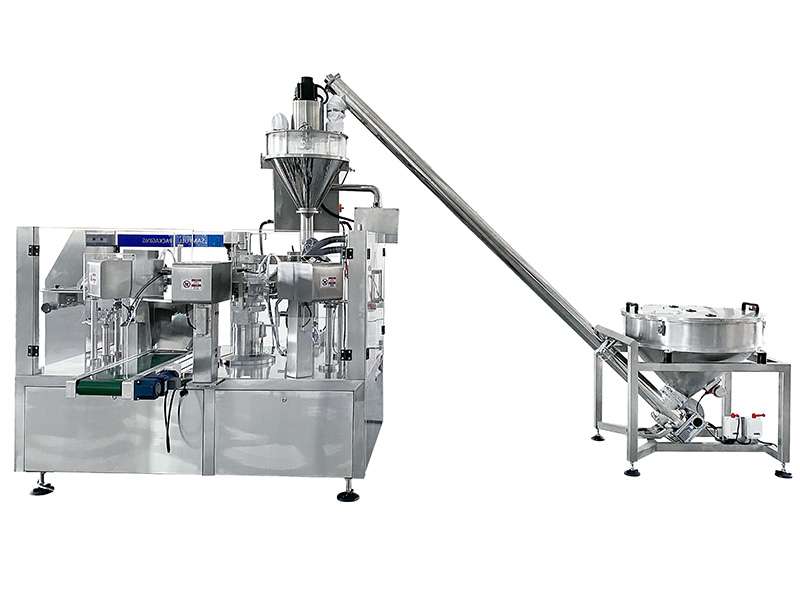

Flour Premade Pouch Doypack Machine

Application

Flour Premade Pouch Doypack Machine is a specialized packaging equipment designed to fill and seal pre-formed pouches with flour or other powdered products. The doypack stand-up pouch with an oval or rounded bottom that allows it to stand upright, making it a popular choice for packaging various food products, including flour.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos

Two lane duplex design 60-100 bags per minute high speed:

Here's how a Flour Premade Pouch Doypack Machine works

1.Pouch Feeding: Pre-formed Doypack pouches are loaded into the machine's magazine or feeding system. The pouches are typically made of flexible packaging materials, such as laminated films, which are capable of withstanding the weight of the flour and maintaining the product's freshness.

2. Pouch Opening: The machine uses mechanical arms or vacuum systems to open the top of each pouch, creating a wide opening for filling.

3. Product Dispensing: Flour is accurately measured and dispensed into each pouch through a filling nozzle or auger system. The precise filling mechanism ensures that the correct amount of flour is deposited into each pouch.

4. Air Removal (Optional): To improve the packaging's appearance and prevent air pockets, the machine may incorporate a step to remove excess air or create a vacuum within the pouch before sealing.

5. Pouch Sealing: Once the pouches are filled with flour, the top is heat-sealed to create an airtight and secure closure. Some machines may also add a zip-lock or resealable feature to the top of the pouch for consumer convenience.

6. Date and Batch Coding (Optional): If required, the machine can apply date codes, batch numbers, or other product information onto the packaging using inkjet or laser printers.

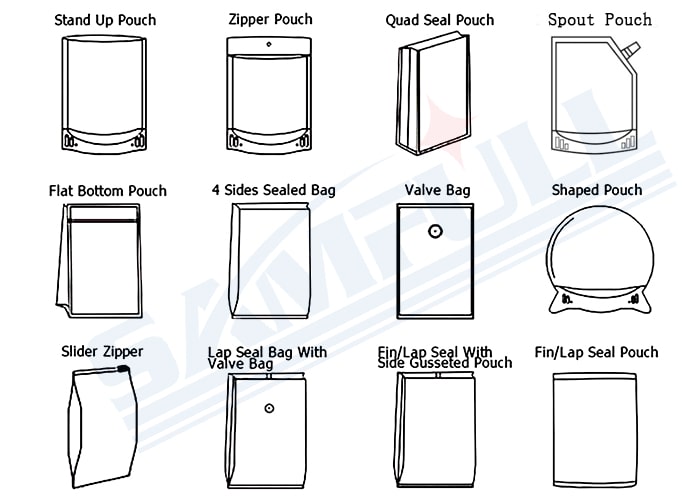

Bag Shape Options

1. Doypack pouch

2. Resealable zipper pouch

3. Quad seal stand up pouch

4. Spouted pouch

5. Pouch with hanging hole

6. Other customized premade pouch

Features

1. Stainless steel appearance, beautiful and high-grade, stable operation;

2. Replace manual packaging, the production efficiency is increased, and the production cost is greatly reduced;

3. Adopt PLC control, touch screen operation, a wide range of use, set the speed of operation according to production capacity requirements;

4. Changing the size of the bags quickly and easily which can be adjusted by handle;

5. Automatic detection function, the pouch can be recycle used if these situation happens: bags can not open or open the bag incomplete, no feeding, no heat sealing;

6. It can be used in doypack bags, handbags, zipper bags, four-sided bags, three-sided bags, paper bags, M-shaped bags and other composite bags;

7. It can automatically perform the functions of suction bag, date printing, bag opening, materials filling, bag sealing, finished product output.